Compressed air quality Qualification

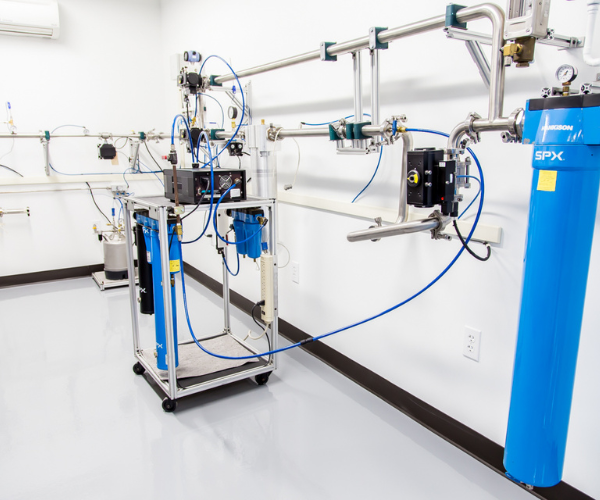

CALLAB offers comprehensive Compressed Air Quality Qualification services to ensure that compressed air systems meet the required standards for safety, purity, and performance in various industrial environments. This service is particularly important in industries like pharmaceuticals, food manufacturing, and medical devices, where air quality is critical to product quality and regulatory compliance.

Our Compressed Air Quality Qualification includes:

- Air Purity Testing: Measurement of oil, moisture, and particulate contamination in compressed air systems to ensure they meet industry-specific purity standards.

- Particle Counting: Assessing the level of particulate matter in the compressed air, ensuring it meets the required clean air standards for sensitive environments.

- Pressure and Flow Measurements: Verifying the adequacy of air pressure and flow within the system to maintain consistent performance and efficiency.

- Dew point/ Water concentration: Since is necessary to prevent instrument damage and minimize process contamination.

Compressed Air System Full Qualification (IQ, OQ, and PQ) in accordance with ISO 8537 standards, specifically tailored for the pharmaceutical and medical industries.

Air Purity Testing

Measurement of oil, moisture, and particulate contamination in compressed air systems to ensure they meet industry-specific purity standards.

Particle Counting

Assessing the level of particulate matter in the compressed air,

ensuring it meets the required clean air standards for sensitive environments.

Pressure and Flow Measurements

Verifying the adequacy of air pressure and flow within the system to maintain consistent performance and efficiency.

Dew point/ Water concentration

Since is necessary to prevent instrument damage

and minimize process contamination.

System Integrity

Checks

Conducting leak tests and pressure drop tests to ensure the integrity of the compressed air system.