Validation & Qualification Services

Validation & Qualification Services Provided by CALLAB (GMP) – Specific

- Callab provide a various Validation activities to validate the sterilization and working process in many pharmaceutical machinery and equipment.

Cleanroom Qualification

- HEPA Filter Integrity Testing

- Particle Counting

- Smoke Testing

- Air Velocity Measurement

- Air Volume Measurement

- Air Change per Hour (ACH) Measurement

- Differential Pressure Measurement

- Light Intensity Measurement

- Sound Level Measurement

Temperature and Humidity Study

- Cold Room

- Deep Freezer

- Storage

- Incubator

- Oven

- Stability Room Monitoring

Compressed Air Quality Qualification

CALLAB offers comprehensive Compressed Air Quality Qualification services to ensure that compressed air systems meet the required standards for safety, purity, and performance in various industrial environments. This service is particularly important in industries like pharmaceuticals, food manufacturing, and medical devices, where air quality is critical to product quality and regulatory compliance. Our Compressed Air Quality Qualification includes: Our qualification services help ensure that your compressed air system operates efficiently, maintains the highest standards of quality, and meets regulatory requirements, protecting both product integrity and operational reliability.

Autoclaves and Sterilizers validation

- Vertical Autoclaves

- Dry heat Autoclaves

- Steam Autoclaves

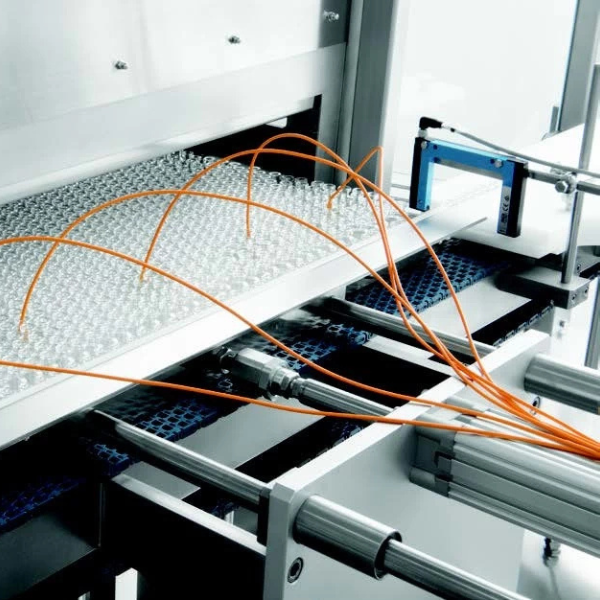

Tunnel Validation

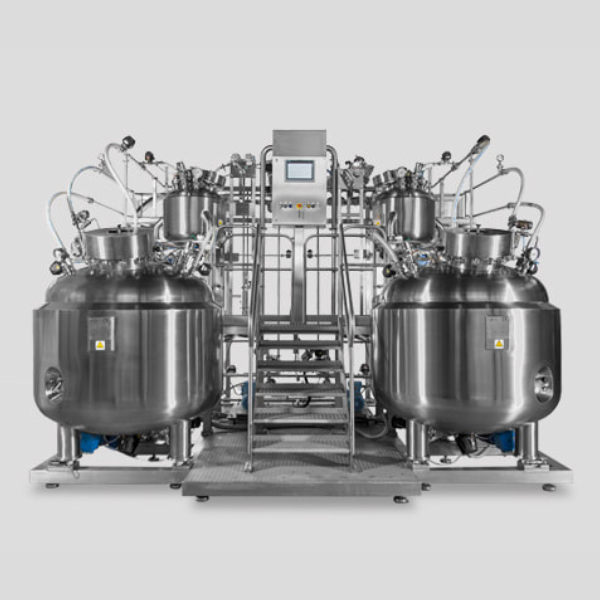

Steam in place (SIP)

- Vessel

- Mixing Tank B

- FS machine

- Filling line

Stability Chamber Stability Room

Vacuum Freeze Dryer / Lyophilizer

Oven/ Furness / CO2 incubator

Temperature Mapping

- Warehouse Storage

- Storage Room

- Truck and Vehicle

Temperature Mapping

- Cold Room

- Deep Freezer

- Refrigerator